6025GH Series High Power Whole Cover Fiber Laser Cutting Machine

Plate Welding Heavy Work Bed

Annealed And Heat Treated

Plate welding heavy work bed, no deformation in 20 years, suitable for ultra-high power 10,000-watt laser. The increase in weight is very beneficial to the laser cutting machine cutting speed.

Innovative Four Slings Working Bed

For reducing damage to the work bed during laser working, G.WEIKE Innovated the new work bed by adding four slings, and the life span of the fiber laser cutting machine work bed will be doubled.

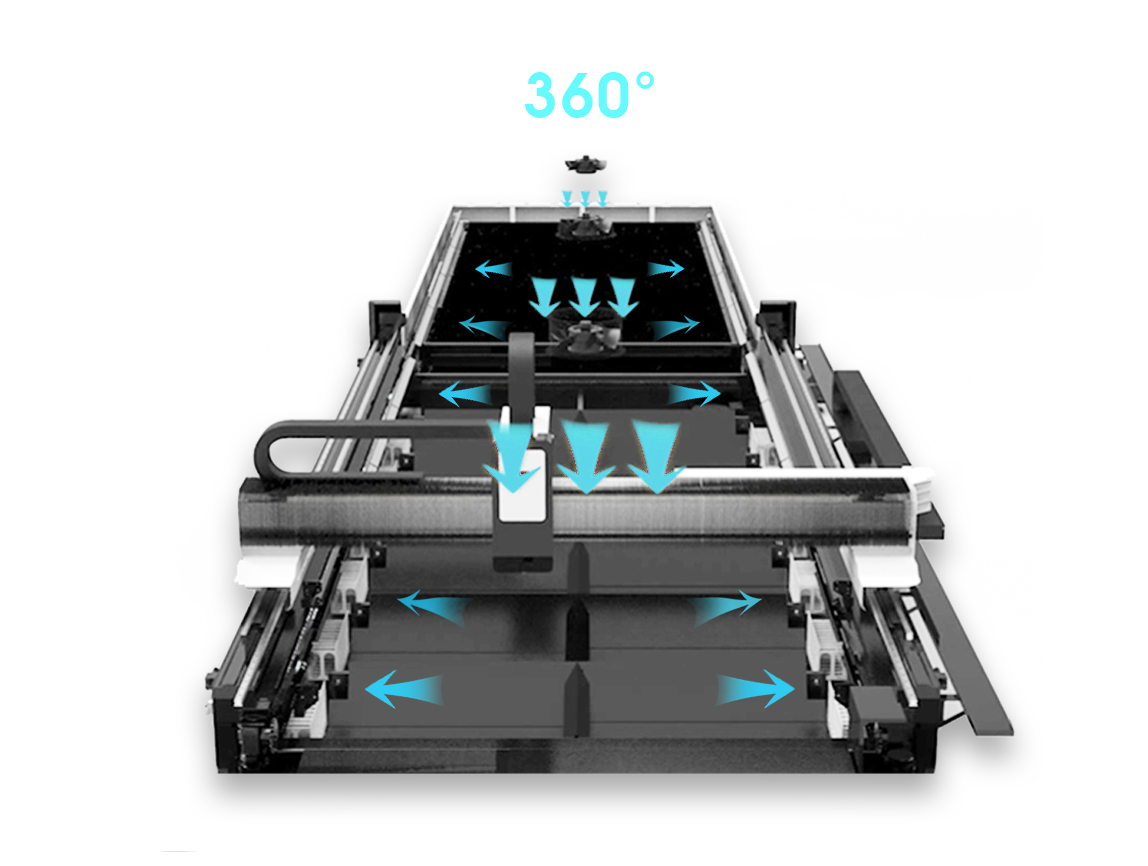

Segmented smoke exhaust-create a smokeless clean world

Full coverage, super suction

Adopt the latest cutting-edge tobacco control technology Each section of the bed has a smoke exhaust device

Powerful negative pressure 360° adsorption

Axial fan wind direction surrounds blowing smoke downward Full 360° strong adsorption and consistent smoke exhaust Effectively purify the smoke and dust on the top of the enclosed cutting platform Improve purification efficiency and reject lens contamination

Net follow-up, wisdom grows by quality

The smoke exhaust device automatically senses the laser cutting position Turn on precise smoke exhaust, follow-up smart smokingCreate a concealed cavity, fully enclosed smoke control and clean smoke

| Machine model | LF4020GH | LF6025GH | LF10025GH | LF12025GH |

| Laser power | 8000W 12000W 15000W 20000W(Optional) | |||

| Dimensions | 11475*2574*5169mm | 14937*3952*2287mm | 22953.5*4006*2336.5mm | 27092*4119*2336.5mm |

| Working area | 4000mm*2000mm | 6000mm*2500mm | 10000mm*2500mm | 12000mm*2500mm |

| Repeat positioning accuracy | ±0.02mm | |||

| Maximum speed | 200m/min | |||

| Max. acceleration | 2.5G | |||

| Voltage and frequency | 380V 50Hz/60HZ | |||